The Role of High-Pressure Water Manifolds in Medical Devices

When it comes to medical devices, precision and quality are of utmost importance. Every component and system must function flawlessly to ensure patient safety and optimal outcomes. One critical component that plays a vital role in numerous medical devices is the high-pressure water manifold. This blog will explore the significance of high-pressure water manifolds in medical devices and their benefits in various healthcare applications.

Understanding High-Pressure Water Manifolds

High-pressure water manifolds are complex systems that control and distribute pressurized water or liquid to different parts of medical devices. These manifolds are engineered to withstand high pressures and deliver precise flow rates, ensuring reliable performance. They are typically made from durable materials such as stainless steel, which is resistant to corrosion and contamination.

Importance in Medical Devices

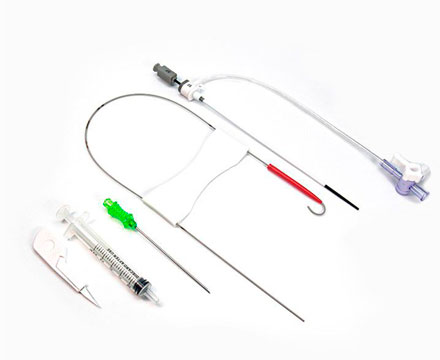

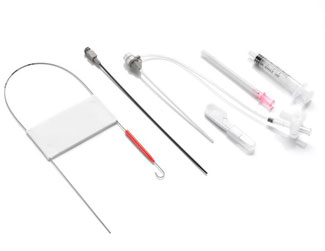

High-pressure water manifolds are critical components in several medical devices. One primary application is in surgical instruments such as powered surgical tools. These instruments require a steady flow of high-pressure water to cool and irrigate the surgical site, minimizing tissue damage and maintaining a clear view for surgeons.

Additionally, high-pressure water manifolds are instrumental in medical imaging devices such as CT scanners and X-ray machines. These devices utilize water to cool the X-ray tube or generator, preventing overheating and maintaining optimal performance. Manifolds ensure a consistent water flow at high pressures, contributing to accurate imaging results and reducing the risk of equipment failure.

Benefits and Advantages

The use of high pressure water manifold in medical devices offers several benefits and advantages:

Improved Performance

High-pressure water manifolds deliver consistent flow rates and pressures, optimizing the performance of medical devices. By ensuring a steady supply of water or liquid, these manifolds enhance the efficiency and accuracy of surgical tools and imaging equipment, ultimately benefiting patients and healthcare providers.

Enhanced Safety

In medical procedures, safety is paramount. High-pressure water manifolds play a crucial role in maintaining a safe working environment. By controlling the flow and pressure of water, these manifolds prevent sudden surges that could damage delicate instruments or harm patients. They also provide a reliable cooling mechanism, reducing the risk of overheating and potential accidents.

Versatility and Customization

High-pressure water manifolds can be customized to suit specific medical device requirements. Manufacturers can design manifolds with varying flow rates, pressure ranges, and connections, depending on the intended application. This versatility allows medical device manufacturers to tailor their products for diverse healthcare settings and user preferences.

Reliability and Durability

Medical devices must endure multiple sterilization processes and frequent usage. High-pressure water manifolds, constructed with robust materials, can withstand these demanding conditions. Their resistance to corrosion and contamination ensures optimal performance and longevity, reducing the need for frequent replacement or repairs.

In conclusion, high-pressure water manifolds play a pivotal role in various medical devices, enabling precise and reliable delivery of pressurized water or liquid. These manifolds contribute to enhanced performance, safety, and versatility in surgical instruments and medical imaging devices. As technology continues to advance, the importance of high-pressure water manifolds in the medical field will only continue to grow, ensuring better patient outcomes and advancing the quality of healthcare.

English

English  日本語

日本語  한국어

한국어  français

français  Deutsch

Deutsch  Español

Español  русский

русский  português

português  العربية

العربية  tiếng việt

tiếng việt  ไทย

ไทย  Malay

Malay  हिंदी

हिंदी